Categories

Aluminum & Aluminum Alloy Rod Continuous Casting and Rolling Production Line

1. Description

☀ Production line is mainly used in the high tensile conductive rod production of 9.5MM, 12.5MM, 15MM aluminum and

aluminum alloy(EC1350,Series No 3#, 5#(5005、5154), 6#(6101/6201) and Series No. 8 (8176, 8030), etc. The

technology of the line can meet the standard of European and American.

☀ The production line is composed by the melting furnace, holding furnaces, four wheel continuous casting machine,

straightening machine, front traction, rolling shear machine, medium-frequency heating furnace, feeding machine,

continuous mill machine, cooling system, take-up rod device and electrical control system.

☀ The crystallization wheel adopts H-type structure, all sides cooling and the ingot casting is dense and uniform. There are

three kinds of combination forms of two rollers type, three rollers type and two rollers + three rollers type for customers

to choose. Provide the production line which output is 4.5 tons, or 7.5 tons per hour.

☀ The electrical control system design is advanced and adopts programmable logic controller (PLC) + human machine

interface (touch screen) control, he electrical control system controls the whole line linkage and monitors the running

status.

2. Equipment Pictures

-

-

3. Technical Parameters

Model | Rod Diameter | Rolling Times | (T/H) Capacity | Roller Mode | (T/H) Melting Furnace Capacity | (T) Holding Furnace Capacity | Furnace Energy | Product Mark |

4.5T | 9.5 12 15 | 15 | 4.5-5 | 3rollers | 6 | 10-15 | Natural gas,LPG | 1、3、5、6、8 |

7.5T | 9.5 12 | 10or14 | 6-7.5 | 2rollers+3rollers | 12 | 20-25 |

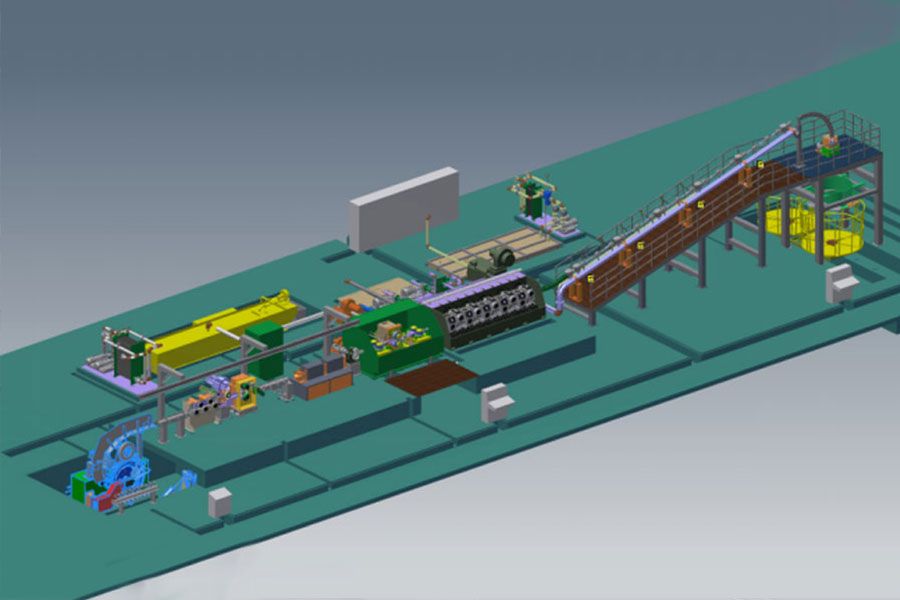

4. Layout

5. Application Demonstration

-

-