Characteristics of stranding machine

Dec 18, 2019|

Dec 18, 2019| View:1840

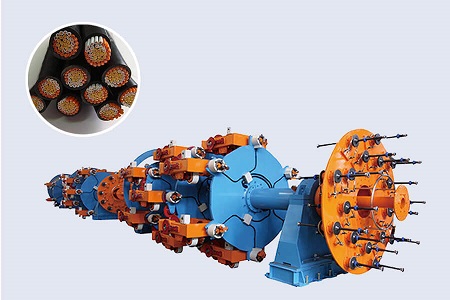

View:1840With the intelligent life, there are more and more types of electrical wires used in life. These wires have different lengths and thicknesses. Observing their cross-sections, they will find that they are twisted together by multiple thin wires. What are the characteristics of the stranding machine formed by twisting them together?

There are many types of stranding machines, which can wind a variety of soft and hard metal wires with different strengths in different equipment. For materials with a short wire cross-section diameter, the equipment used for processing is relatively small. The thickness of the wire that can be accepted by each device is different. The larger the cross section of the wire within the acceptable range, the larger the volume of the device. When selecting the device, you should focus on your actual needs, not on Reduce your footprint and choose blindly.

The equipment adopts fully automatic operation, which can control the operation or suspension of the equipment with one button. When the stranding machine is running too long, multiple people are not required to operate, and even multiple machines can be operated by only one person, which saves time and effort and improves work efficiency.

The number of strands that the device can carry ranges from two to eight, and the wires made according to the different uses of the wire have different uses, so it can be used in many industries.The product made by the stranding machine will not be exposed in the air, and it will be covered with different points of rubber material as a protection, so in life we can only see the thinner rubber entangled together. Users who are interested in the twisting machine can contact us and look forward to your visit.

E-mail: sales1@rlbcable.com

E-mail: sales1@rlbcable.com English

English العربية

العربية Le français

Le français

View More(Total0)Comment lists