Categories

Aluminum Conductor Composite Core

1. Definition

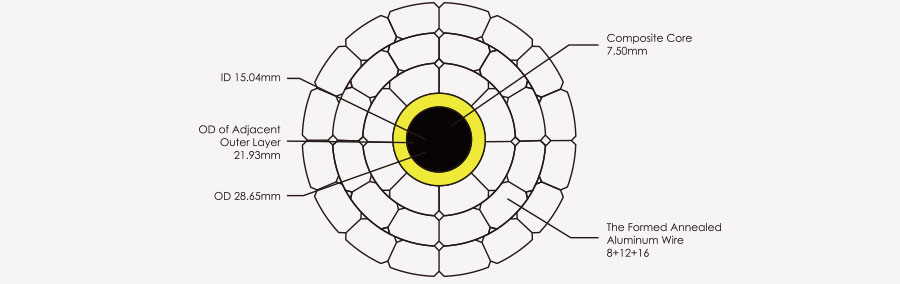

Is a high capacity, low slag conductor which consists of a carbon fiber composite core encased in a protective fiberglass

sheath that is helically wrapped with high purity conductive aluminum strands.

2. Application

It is a new type of overhead transmission line conductor, its outstanding characteristics are light weight, tensile resistance,

good thermal stability, small relaxation, strong flow capacity per unit area and corrosion resistance. Especially suitable for

the company's resident coastal, mining areas with high corrosion intensity, pollution intensity, easy to run wire operating

environment.

3. Standard

GB/T 32502—2016; Q/320282 DFP08—2017; Q/320282 DFP05—2017.

4. Packing

Wooden Steel Wood Drum or Steel Drum.

5. Technical Parameter

Aluminum Conductor Composite Core | Cond. | Dia. | Core Dia. | Weight | Core Related Strength | Cond. Rated Strength | Aluminum Conductor Composite Core | Cond. | Dia. |

International Sizes | (kcmil) | (mm2) | (mm) | (mm) | (kg/km) | (kN) | (ohm/km) | 180°C | 200°C |

Copenhagen | 434 | 219.9 | 18.29 | 5.97 | 661 | 60.4 | 0.2094 | 1,017 | 1,070 |

Lisbon | 623 | 315.5 | 21.79 | 7.11 | 948 | 85.7 | 0.1460 | 1,284 | 1,353 |

Brussels | 832 | 421.4 | 25.15 | 8.13 | 1265 | 112.0 | 0.1097 | 1,549 | 1,632 |

Hamburg | 1078 | 546.4 | 28.63 | 8.76 | 1627 | 130.2 | 0.0846 | 1,834 | 1,935 |

Milan | 1120 | 567.7 | 29.11 | 8.76 | 1686 | 130.2 | 0.0813 | 1,880 | 1,984 |

Rome | 1169 | 592.5 | 29.90 | 9.53 | 1774 | 153.8 | 0.0780 | 1,935 | 2,043 |

Vienna | 1242 | 629.2 | 30.43 | 8.76 | 1853 | 130.2 | 0.0733 | 2,007 | 2,119 |

Munich | 1447 | 733.1 | 32.84 | 9.53 | 2170 | 153.8 | 0.0632 | 2,211 | 2,336 |

London | 1498 | 759.0 | 33.40 | 9.78 | 2248 | 162.1 | 0.0609 | 2,264 | 2,392 |

Paris | 1606 | 813.7 | 34.16 | 8.76 | 2366 | 130.2 | 0.0568 | 2,358 | 2,492 |

Berlin (Madrid-lce) | 1986 | 1006.5 | 38.20 | 10.54 | 2949 | 188.3 | 0.0458 | 2,713 | 2,872 |

Madrid | 1999 | 1013.0 | 38.20 | 9.78 | 2948 | 162.1 | 0.0454 | 2,721 | 2,880 |

Athens | 2782 | 1409.6 | 44.75 | 10.54 | 4066 | 188.3 | 0.0328 | 3,335 | 3,538 |

Ampacity values based on 50 Hz, zero elevation, 90° sun altitude, 25 °C ambient temperature, 0.5 Solar Absorbtivity, 0.5

Emissivity, 0.61 m/sec wind and 96 1,033 W/m2, at corresponding surface temperatures. Coefficient of thermal resistance

is 0.00403 for international sizes.

6. Product Type

Type | Shape | Dia. of core mm | Area of Al mm2 | Rate break loading KN | Unit weight Kg/km | 20°C DC Ω/km | Line expansion Factor X10-6 1/℃ | |

Under turning point | Above turning point | |||||||

The formed annealed aluminum conductors composite core supported | ||||||||

95/30~800/95 | 6.00~11.00 | 95~800 | 64.85~245.7 | 318.5~2406.5 | 0.2939~0.0351 | 15.1~18.9 | 1.8 | |

Thermal-resistant Aluminum-alloy Conductors Composite Core Reinforced | ||||||||

150/35~630/70 | 6.50~9.50 | 182.0~710.8 | 76.97~213.4 | 477.40~1907.45 | 0.1972~0.0459 | 16.5~19.2 | 1.8 | |

Formed Intermediate Aluminum Conductors Composite Core Supported | ||||||||

95/30~1660/95 | 6.00~11.00 | 95~1660 | 69.30~373.0 | 317.19~4811.7 | 0.0173~0.2971 | 15.2~20.8 | 1.8 | |

150/35~630/70 | 6.50~9.50 | 182.00~710.80 | 83.94~228.27 | 477.40~1907.45 | 0.0459~0.1972 | 16.5~19.2 | 1.8 | |

The High-elongation Hard Aluminum ConductorsComposite Core Reinforced | ||||||||

150/30~630/70 | 6.00~9.50 | 154.2~639.9 | 73.7~221.5 | 482.0~1910.2 | ≤0.1871 | 17.3~19.2 | 1.8 | |

The High-conductivity (62.5% IACS) Aluminum ConductorsComposite Core Reinforced | ||||||||

150/30~630/70 | 6.00~9.50 | 154.2~639.9 | 72.1~213.6 | 479.1~1903.8 | ≤0.1841 | 17.3~19.2 | 1.8 | |