Categories

Aluminum Alloy Wire

1. Application

It is widely used as single wire of aluminum alloy stranding wire and electrician.

2. Standard

GB/T3954-2008

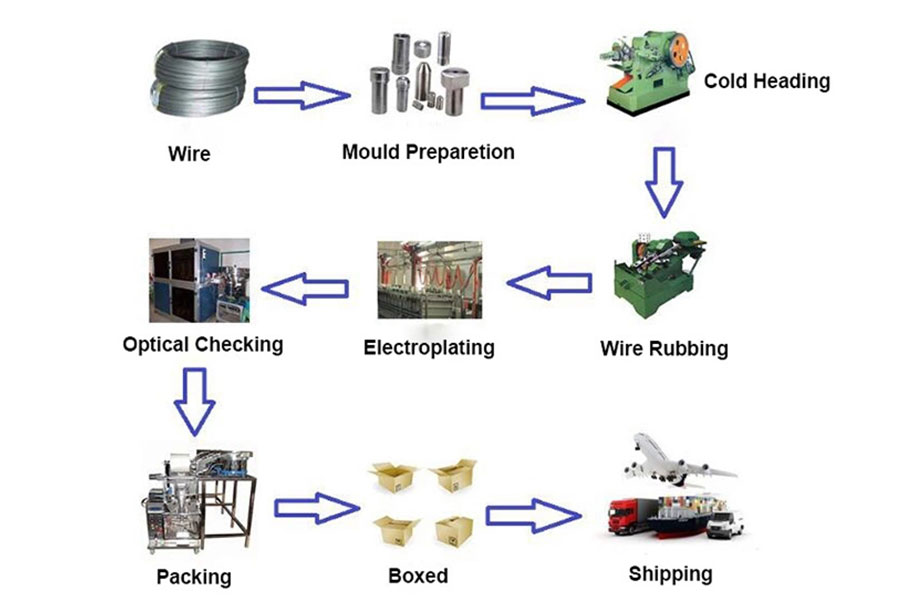

3. Production process

4. Packing

Plywood Pallet

5. Specification & Parameter

6201 Aluminum Alloy Wire6201

Temper | Tensile Strength (MPa) | Elongation (%,min) | Resistivity (20℃,nΩ•m,max) | Conductivity (%,min) |

LHA1 | 315-325 | 3 | 32.840 | 52.5 |

LHA2 | 295 | 3.5 | 32.530 | 53 |

Note: diameter ≤ 3.50, tensile strength >325. diameter> 3.50, tensile strength > 315.

6101 Aluminum Alloy Wire6101

Temper | Diameter | Tensile Strength (MPa,min) | Elongation (%,min) | Resistivity (20℃,nΩ•m,max) | Conductivity (%,min) |

LHA3 | 2.00≤d<3.00 | 250 | 3.5 | 29.472 | 58.5 |

3.00≤d<3.50 | 240 | ||||

3.50≤d<4.00 | 240 | ||||

4.00≤d<5.00 | 230 | ||||

LHA4 | 2.00≤d<3.00 | 290 | 3.0 | 30.247 | 57.0 |

Thermal-resistant Aluminum Alloy Wire

Type | Diameter | Tensile Strength (Mpa,min) | Elongation (%,min) | Conductivity (%,min) |

Nrlh1 Allowable Continuous Operating Temperature (40 Years) 150°C | 2.60<d≤2.90 | 166 | 1.6 | 60 |

2.90<d≤3.50 | 162 | 1.7 | ||

3.50<d≤3.80 | 162 | 1.8 | ||

3.80<d≤4.00 | 159 | 1.9 | ||

4.00<d≤4.50 | 159 | 2.0 | ||

Nrlh2 Allowable Continuous Operating Temperature (40 Years) 150°C | 2.60<d≤2.90 | 245 | 1.6 | 55 |

2.90<d≤3.50 | 241 | 1.7 | ||

3.50<d≤3.80 | 241 | 1.8 | ||

3.80<d≤4.00 | 238 | 1.9 | ||

4.00<d≤4.50 | 225 | 2.0 |