Categories

Enameling Wire Production Line

1. Description

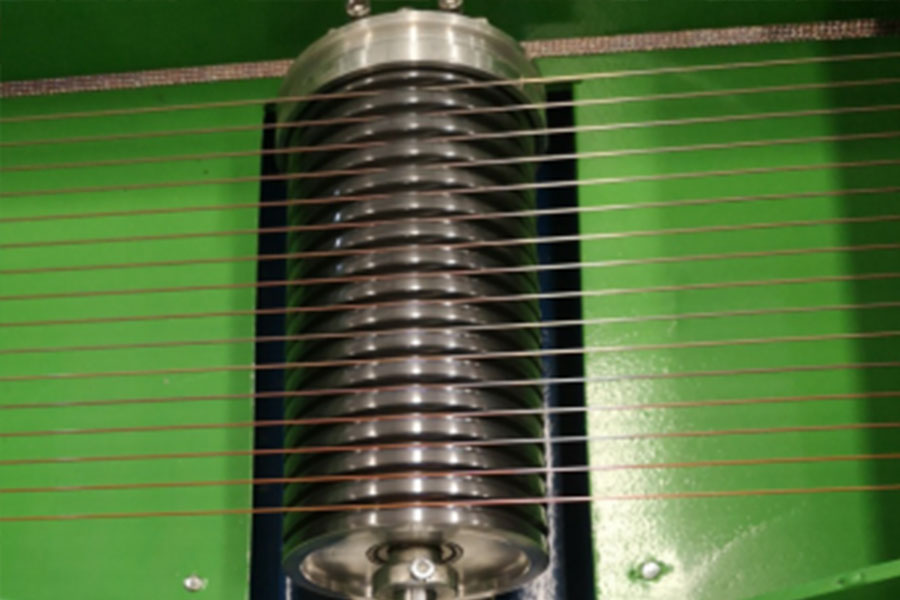

We provide low speed copper wire enameling machine, low speed al wire enameling machine, cu & al wire vertical

enameling machine. The enameling production line is to cover the processed copper wire ( or aluminum wire ) with a layer

of insulating polyvinegar paint. According to the market demand, we have copper and aluminum wire drawing, enamelled

integration production line, in order to save human resources.

2. Equipment Picture

-

-

3. Technical Parameters

Name | Machine model | Material | (mm) Wire range | Lines | Max. passes | DV value | Take up spool size | Kgs/24Hrs Out put | Mg/m3 Environment data VOC |

Horizontal enameling machine | RLBHE1- 2800-24 /10-S | Copper | Φ0.04-Φ0.07 | 24 | 9(Dual coating) | 24/PU | PT2-PT4 | 290(Φ0.05) | ≤20 |

RLBHE2- 3000-28 /8-S | Copper | Φ0.06-Φ0.10 | 28 | 10(Dual coating) | 22/PU | PT2-PT10 | 540(Φ0.08) | ≤20 | |

RLBAHJ4 /4000-32 /8-S | Copper | Φ0.10-Φ0.30 | 32 /28 /24 | 8(Dual coating) | 25/PE | PT4-PT25 | 1600(Φ0.20) | ≤20 | |

RLBAHJ5 /4800-18 /10-D(LD2) | Copper | Φ0.25-Φ0.55 | 20 | 9(Dual coating) | 25/PE | D(PT10-PT45)/LD2 (PT25-PT270) | 2000(Φ0.40) | ≤20 | |

RLBAHJ6 /5200-18 /10-D(LD2) | Copper | Φ0.40-Φ0.80 | 18 | 10(Dual coating) | 25/PE | D(PT10-PT45)/LD2 (PT25-PT270) | 2370(Φ0.60) | ≤20 | |

RLBAHL4 /4000-24 /10-S | Aluminum | Φ0.15-Φ0.35 | 24 | 10(Dual coating) | 25/PE | PT4-PT25/ PT25-PT60 | 380(Φ0.20) | ≤20 | |

RLBAHL5 /4800-18 /10-D(LD2) | Aluminum | Φ0.30-Φ0.60 | 20 | 9(Dual coating) | 23/PE | D(PT10-PT60/ PT25-PT90)/LD2 (PT25-PT90) | 600(Φ0.40) | ≤20 | |

RLBAHL6 /5200-18 /10-D(LD2) | Aluminum | Φ0.50-Φ1.20 | 18 | 10(Dual coating) | 23/PE | D(PT10-PT60/ PT25-PT90)/LD2 (PT25-PT90) | 1000(Φ0.80) | ≤20 | |

RLBHL6 /5200-12 /13-9FA | Aluminum | Φ0.40-Φ1.20 | 12 | 13(Dual coating) | 30/PE | LD&LD2(PT90-PT200) | 700(Φ0.80) | ≤20 | |

Vertical enameling machine | RLBV 8000-1 /19*2-6 | Copper | Φ0.80-Φ1.50 | 38 | - | 25 | - | 3300(Φ1.20) | ≤20 |

Aluminum | Φ0.80-Φ1.80 | 38 | - | 25 | - | - | ≤20 | ||

RLBV 8000-1 /14*2-8 | Copper | Φ1.20-Φ2.50 | 28 | - | 25 | - | 4240(Φ2.0) | ≤20 | |

Aluminum | Φ1.20-Φ2.80 | 28 | - | 25 | - | - | ≤20 | ||

RLBV 8000-1 /8*2-9 | Copper | Φ0.80-Φ3.0 | 16 | - | 25 | - | 2420(Φ2.0) | ≤20 | |

Aluminum | Φ0.80-Φ3.50 | 16 | - | 25 | - | - | ≤20 | ||

Vertical drawing and enameling machine | RLBV 8000-1 /6*2-9F | Copper | Φ1.0-Φ2.50 | 12 | - | 35 | - | 8400(Φ2.0) | ≤20 |

Aluminum | Φ1.0-Φ2.80 | 12 | - | 35 | - | 2545(Φ2.0) | ≤20 | ||

Drawing and enameling machine | RLBH 6000-1 /6*2-14FE | Copper | Φ0.15-Φ0.35 | 12 | 12 | 55 | PT4-PT25 | 1260(Φ0.18) | ≤20 |

RLBH 6500-1/4* 2-9FB(HB) | Copper | Φ0.40-Φ0.80 | 8 | 15 | 70 | PT25-PT270 | 3360(Φ0.60) | ≤20 | |

RLBH 6500-1/4* 2-9FB(HB) | Copper | Φ0.20-Φ0.40 | 8 | 15 | 70 | PT25-PT90 | 1680(Φ0.30) | ≤20 | |

RLBH8600-4/4 | Copper | Φ0.30-Φ0.80 | 8 | 24 | 120 | PT25-PT270 | 2400(Φ0.50) | ≤20 | |

Copper | Φ0.50-Φ1.20 | 10 | 24 | 120 | PT25-PT90 | 3850(Φ0.80) | ≤20 | ||

Aluminum | Φ0.70-Φ1.20 | 10 | 24 | 120 | PT25-PT90 | 1166(Φ0.80) | ≤20 |

4. Layout

5. Application Domonstration

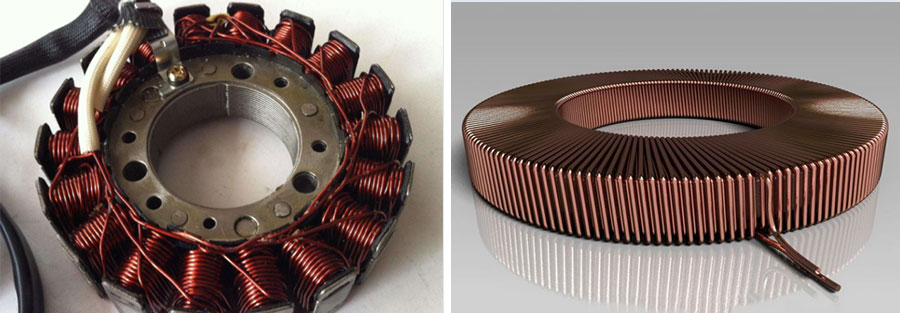

☀ General purpose (normal wire) :It is mainly used for the winding wire of normal motors, electrical appliances, instruments,

transformers and other workplace. such as polyester enameled wire, modified polyester enameled wire.

☀ Heat-resistant enameled wire: it is mainly used for winding wires of motors, electrical appliances, instruments, transformers

and other work places at temperature of 180℃ or above.such as polyester imide enameled wire, polyimide enameled wire,

polyester enameled wire, polyester imide and polyamide-imide composite enameled wire.

☀ Special Purpose: the winding wire with certain quality characteristics is required for specific occasions.such as polyurethane

enameled wire (direct weldability)/self-adhesive enameled wire.

-

-