Categories

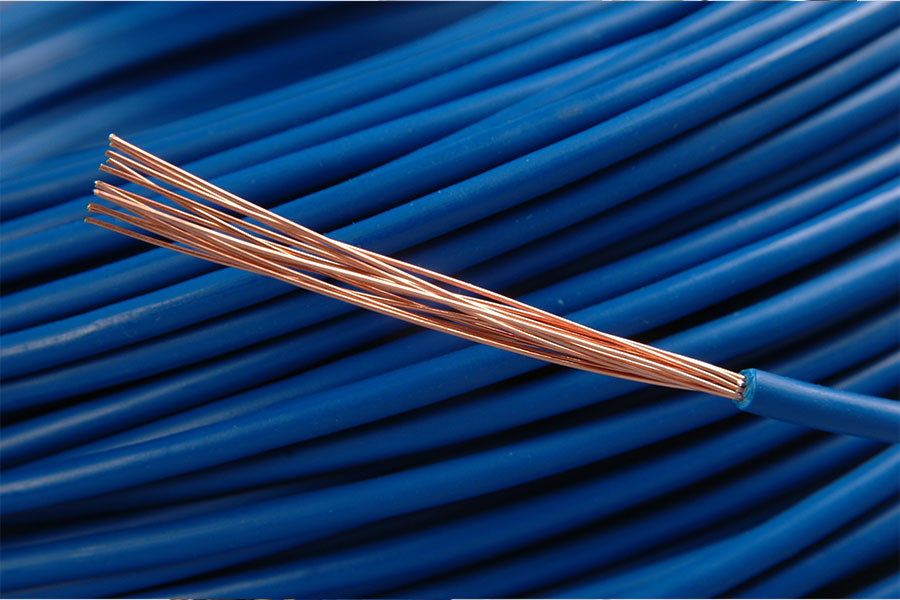

Building Wire Extrusion Production Line

1. Description

☀ Building Wires insulation lines suitable for several thermoplastic compounds such as PVC, PE, XLPE and LSHF.

☀ Optionally the insulation line can be equipped with a co-extruder for color skinning & stripping purposes.

☀ Our range is completed with THHN insulation lines by including a tandem extruder for PA (Nylon) outer jacketing

☀ It features MMI+PLC control, outer diameter feedback. The process parameters can be modified, stored, adjusted and

it is convenient for operation.

☀ Different take up devices can be configured as required.

☀These machines can be selected according to requirements: automatic feeding machine, granule dryer, metering color

master machine, diameter gauge, inkjet machine (laser, ink), frequency spark tester and other auxiliary machines.

2. Equipment Picture

-

-

3. Technical Parameters

Model | RLBEH-75 | RLBEH-90 | RLBEH-100 | RLBEH-120 |

Cross Section mm2 | 1.5-6 | 1.5-10 | 1.5-16 | 1.5-16 |

Finished mm | 6 | 8 | 10 | 14 |

Max Line Speed m/min | 600 | 800 | 900 | 1200 |

-

Model | RLBEW-90 | RLBEW-100 | RLBEW-120 | RLBEW-150 |

Cross Section mm2 | 10-50 | 10-70 | 16-150 | 25-240 |

Finished mm | 15 | 20 | 25 | 30 |

Max Line Speed m/min | 100 | 150 | 250 | 350 |

4. Application

☀These machines can be selected according to requirements: automatic feeding machine, granule dryer, metering color

machine, outer diameter measurement and control, inkjet machine (laser, ink), frequency spark testing machine and other

auxiliary machines.

☀Different take up devices can be configured as required.

☀It can be connected online: coil winding envelop machine, coil taping and heat shrinkable envelop machine, coiling

machine, etc.

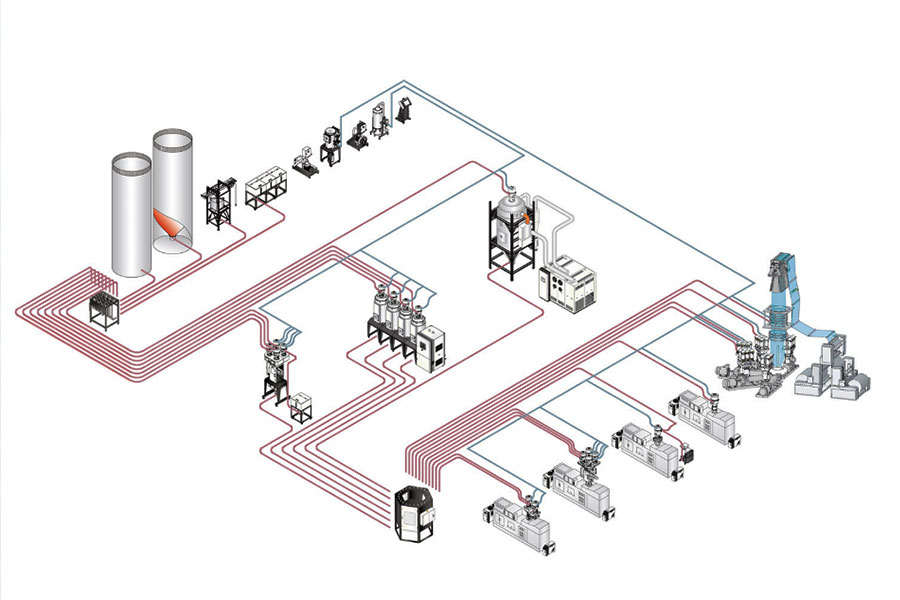

☀It can provide the solution of the whole factory material transportation .

-------------------------------------The solution of the whole factory material Transportation

-

-

---------------------Vacuum conveyor----------------------------------------------------Hopperdryer