Categories

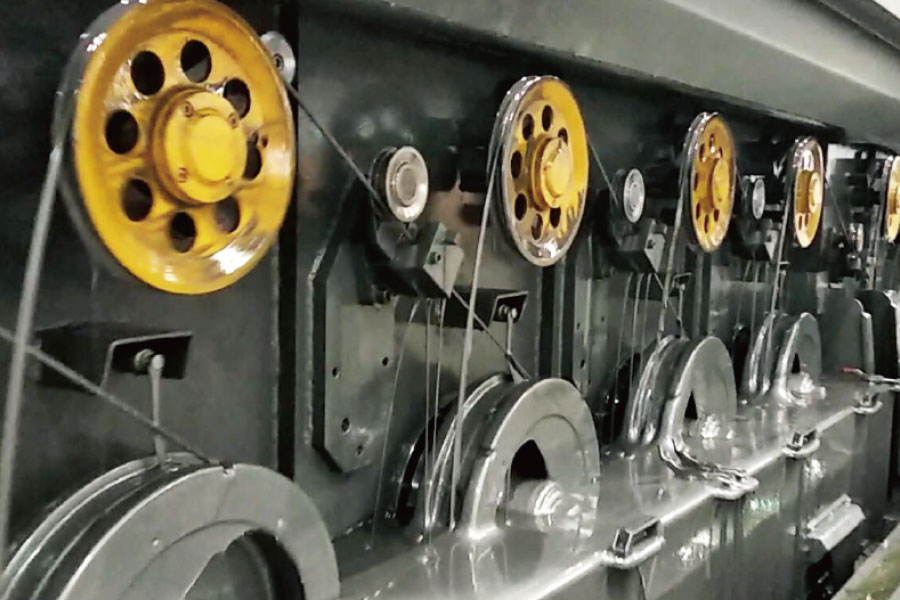

Aluminum Rod Breakdown Machine with Individual Motors

1. Description

This machine is used to produce aluminum wires sized φ1.6-4.5mm from aluminum rods of φ9.5mm or wire φ2.0- 4.0mm

from aluminum alloy rods of φ9.5mm. The drawing capstan is arranged in straight line and in a continuous order. Each

twin-capstan is drove by single Servo motor. The machine speed gets well along with the electric speed so as to change

dies quickly as well as to meet different aluminum material. It is highly praised for easy operation, high efficiency and

excellent wire quality.

☀ Used for drawing round and irregular line of aluminum and aluminum alloy rod;

☀ Provide straight gear drive and separate motor drive wire drawing machine, at the same time can be selected with single

or double head wire drawing machine;

☀ This machine is used to produce aluminum wires sized φ1.6-5.5mm from aluminum rods of φ9.5mm or wire φ2.0- 4.5mm

from aluminum alloy rods of φ9.5mm.

☀ Each drawing ring is independently driven by a motor. Each compression ratio can be set appropriately, convenient for

mold matching. Can meet a variety of grades of aluminum wire drawing.

☀ Optional: annealer can be equipped to realize aluminum alloy wire online annealing;

☀ Optional: single spooler, double automatic spooler, vertical pay-off or combination of various take-up forms;

☀ Using MMI+PLC control system, production line synchronization control, online monitoring, process parameters can be

modified in the touch screen, storage, reading, simple and fast operation;

☀ Threading machine, heat exchanger, steam generator and filter are available for customer choice.

2. Equipment Pictures

3.Technical parameters

Drive Mode | Model | Inlet Dia (Mm) | Wires | Outlet Dia (Mm) | Max. Speed (M/S) | Max Drawing Pass | Capstan Dia(Mm) | Installed Capacity (Kva) | Overall Dimension (M) |

Shunt Drive | LWHD-450/9 | Φ9.5 | 1 | Φ2.5-φ4.5 | 25 | 9 | φ450 | 300 | 22x6x5 |

LWHD-450/11 | Φ9.5 | 1 | Φ2.0-φ4.5 | 30 | 11 | φ450 | 350 | 24x6x5 | |

LWHD-450/13 | Φ9.5 | 1 | φ1.6-φ4.5 | 30 | 13 | φ450 | 400 | 26x6x5 | |

LWHD-450/11(2) | 2*Φ9.5 | 2 | Φ2.0-φ4.5 | 30 | 11 | φ450 | 600 | 24x10x5 | |

In-Line Gear Drive (Single Motor) | LWHD-450/9 | Φ9.5 | 1 | Φ2.5-φ4.5 | 25 | 9 | φ450 | 300 | 22x6x5 |

LWHD-450/11 | Φ9.5 | 1 | Φ2.0-φ4.5 | 30 | 11 | φ450 | 350 | 24x6x5 | |

LWHD-450/13 | Φ9.5 | 1 | φ1.6-φ4.5 | 30 | 13 | φ450 | 400 | 26x6x5 | |

LWHD-450/11(2) | 2*Φ9.5 | 2 | Φ2.0-φ4.5 | 30 | 11 | φ450 | 600 | 24x10x5 | |

Take-up form (optional) 1: 630Single bobbin take-up 2: 630Dual bobbin take-up 3: 800Single bobbin take-up 4: 800Dual bobbin take-up 5: 820Vertical pay-off 6: Or above combination | |||||||||

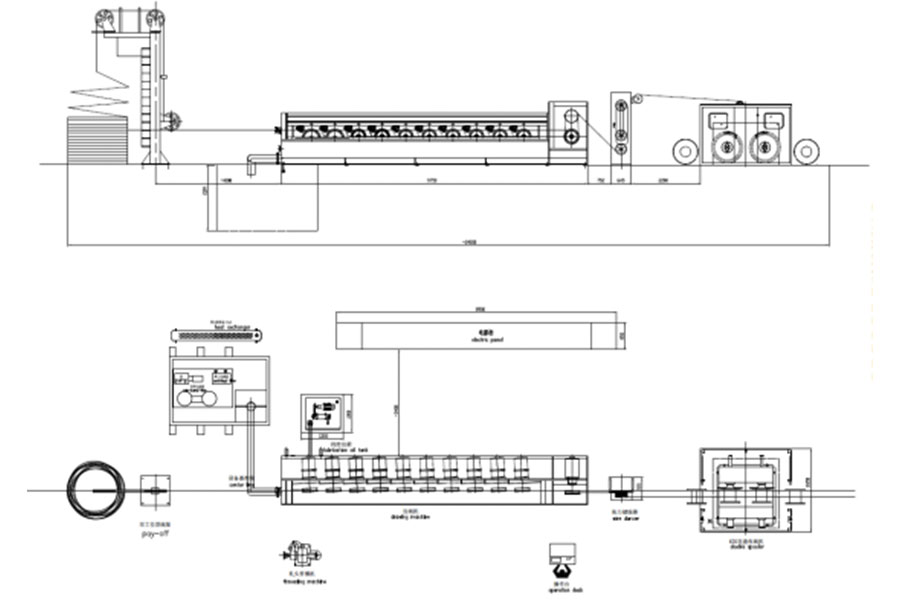

4. Layout

5. Application Demonstration

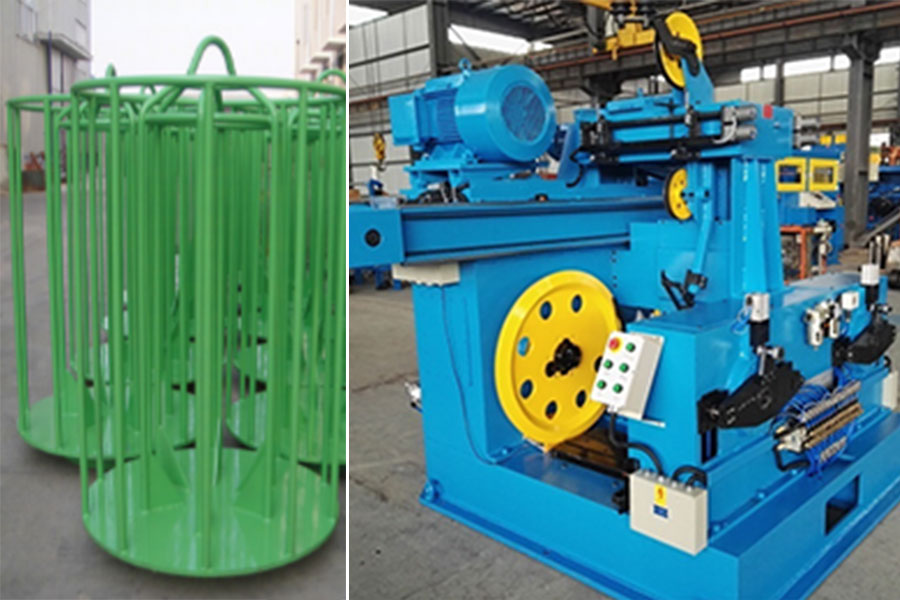

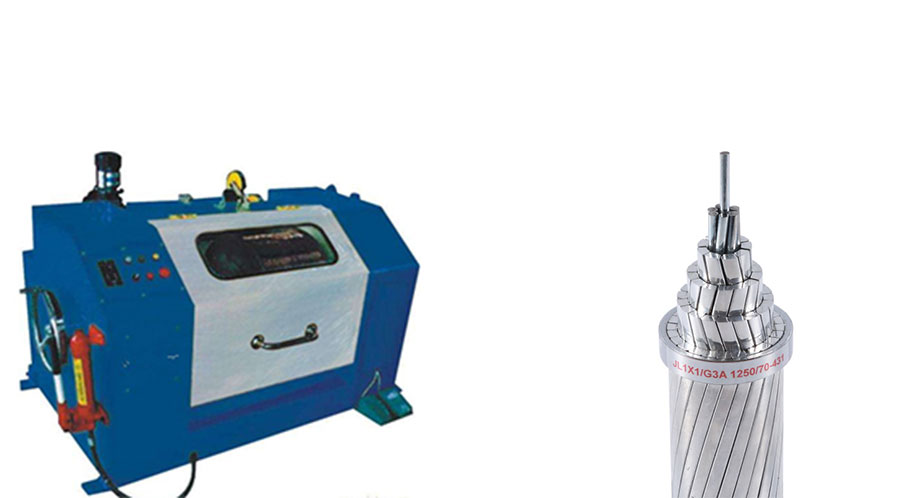

☀Application Demonstration: According to the need, it can be configured with a variety of take-up machine.

☀Suitable for drawing round and irregular conductors.

☀ Annealer can be equipped to realize aluminum alloy wire online annealing.

----Basket take-up------Dual bobbin Automatic take-up------------Single bobbin take-up