Categories

Aluminum Sheath Corrugated Pipe Continuous Extrusion Line

1. Description

☀ The machine is used for aluminum sheath of low-voltage, MV and HV and EHV cable core.

☀ Compared with welding aluminum sheath, aluminum layer is more evenly distributed, without welding defects.

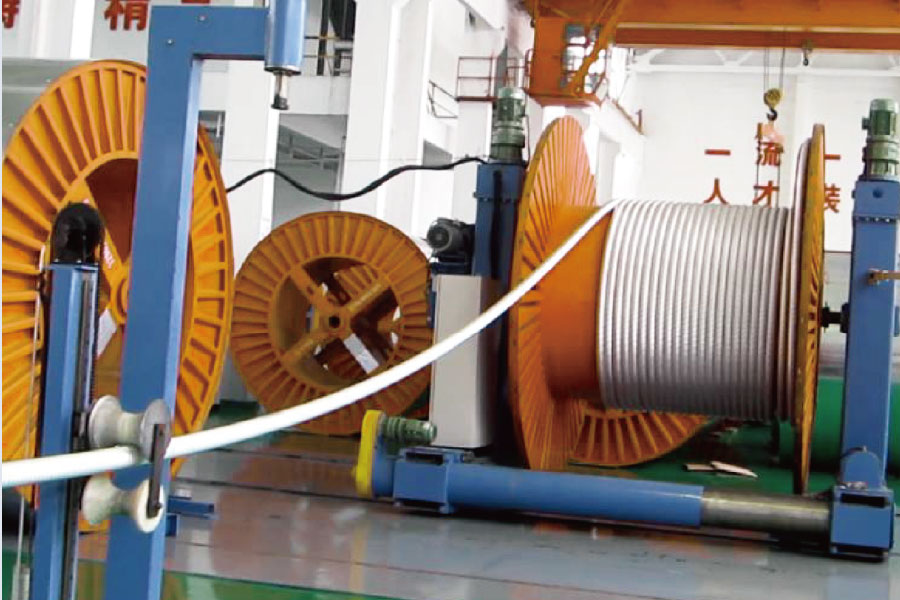

2. Equipment Pictures

-

-

1) The machine use 4 pcs of Φ9.5mm aluminum rod(A2 rod, According to China National Standard GB/T3954) feeding into

the main extrusion machine after surface cleaning treatment to apply Φ60-Φ170mm aluminum sheath.

2) The extrusion main machine use upper and lower single wheel double groove structure, with advanced forming

technology and high production efficiency.

3) After the cable core is paid off from the pay off stand, and go through into the extrusion mold with the same speed of

the aluminum sheath tube, forming a loose cable aluminum sheath. When the cable through the extrusion mold, there is

a water cooling jacket protecting the cable core.

4) After the aluminum tube come out from the extrusion mold, it will be cooled by the cooling water immediately to avoid

any scald to the cable core.

5) The sheathed cable goes into the corrugation unit to corrugate the aluminum tube to form a protection metal sheath of

cable as per the standard or user’s requirement. Then the corrugated aluminum sheath cable will be taken up.

3. Technical Parameters

Model | Inlet | Dia.of Extrusion While | OD of Al. Tube | Thickness of Al. Tube | Pitch of Al. tube | Depth of Al. corrugate | Pay-off Bobbin size | Take-up Bobbin size |

mm | mm | mm | mm | mm | mm | mm | mm | |

LBF420x2 | 9.5±0.3mm | 420 | 60-170 | 1.5-5.0 | 10-50 | 2-8 | 4500 | 4500 |

LBF540x2 | 12±0.3mm | 540 | 60-180 | 1.5-5.0 | 10-50 | 2-8 | 4500 | 4500 |

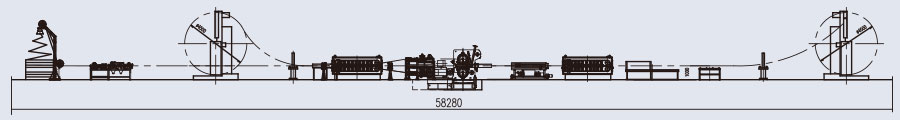

4. Layout

5. Application Demonstration

☀ Continuous extrusion and rolling forming of aluminum sheath of low voltage, medium and high voltage, ultra-high

voltage cable core.