Categories

Three-layer Co-extrusion Dry Cross-linking Production Line

1. Description

☀ For 10-132kv polyethylene power cable compressed copper or aluminum stranded cable core: internal screen,

insulation, external screen three layer co-extrusion and cross-linking;

☀ This line is used for making medium and high voltage power cable and it consists of pay-off stands, take-up stands,

accumulator, caterpillars, extruders, three layers crosshead,tubes, sag device and other single machines.

☀ Dry chemical cross-linking method can produce 10-132KV PE cable, the form of the distribution tube is catenary type,

the cross-linking tube adopts short circuit heating, nitrogen cross-linking and water cooling.

☀ Internal and external shielding and insulation of the cable can extrude and continuous produce at the same time.

☀ In the cross-linking pipeline, the cable can occur chemical cross-linking reaction with certain process line speed

(reaction time) at the protection of high temperature, high pressure and nitrogen. Cooling gradually in the pre-cooling

tube, cooling in the water cooling pipeline, and the final product are produced to ensure the cable has a good electrical

insulation property, anti-aging property and thermal mechanical property.

☀ Using MMI+PLC control system, each production process data can be online: storage, retrieval, modification, intuitive

operation, simple, convenient.

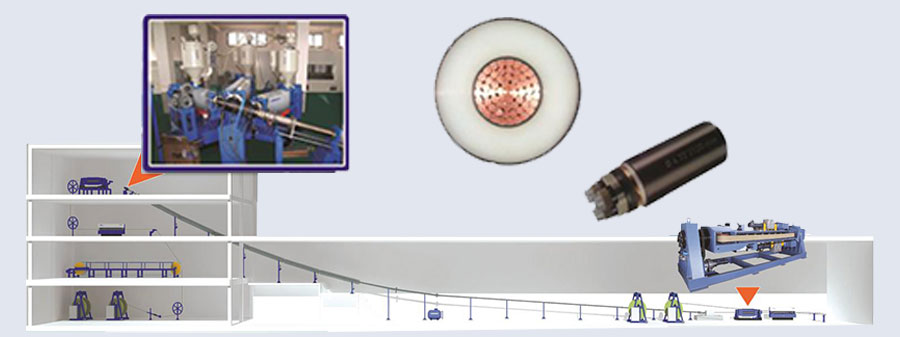

2. Equipment Pictures

3. Technical Parameters

Voltage Grade | Cross-linking polyethylene: 10-35-66-110-132KV | ||

Product Size | Copper core: 50-1600mm² Aluminum core: 70-1600mm² | ||

Cable Max. Weight | 25kg/m | ||

Cable Max. Diameter | 100mm | ||

Cable Structure | Conductor screen 0.5-3.0mm | Insulation 3.4-20mm | Insulation screen 0.5-3.0mm |

Line Speed | 0-15m/min | ||

Tube Type | Half catenary | ||

Length Of Heating tube | Approx 54m, 9 heating tubes(7 or 8 heating tubes) | ||

Pre-Cooling Tube | 12m (2 tubes) | ||

Length Of Cooling Tube | 102m (17tubes)(13 or 15 tubes) | ||

Extruder Arrangement | 80 Conductor screen175 XLPE100 Insulation screen | ||

Electricity | Installation capacity: 1080KVA | 380V±10% 50Hz | 3 Phase 4 Wire |

Water | Water pressure0.2-0.6Mp | Water consumption: 0.2-0.6MP12.5m³/ water in revelant | |

Compressed Air | 0.6-0.8 Mpa | Air consumption: 0.8m³/min | |

Nitrogen | Pressure: 2.0-2.5Mpa | Purity: 99.5% | Consumption: 0.8-1m³/h |

Nitrogen Storage Tank | 5m3 | ||