Categories

Water-blocking Tape

1. Application and Feature

It is a combination of tape, yarn, or coating to prevent longitudinal penetration of water into the cable core .The main

principle is to use a kind of polymer that can absorb water and quickly form gel to fill the seepage channel through the

expansion of hydrogel. It is widely used In optical fiber cable, data cable, telecom cable and control cable.

Proven high performance of swelling and water blocking

Process friendly

REACH and RoHS compliant

2. Section Diagram

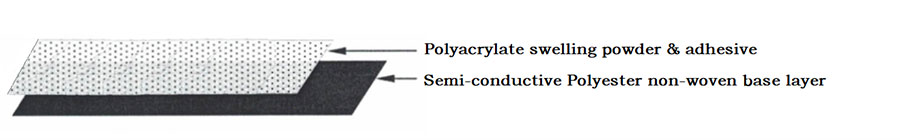

Single Side

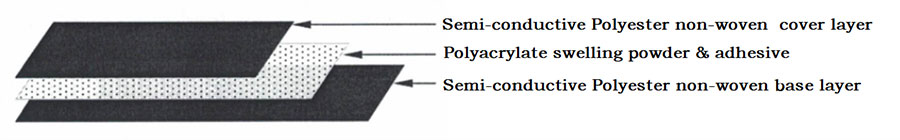

Double sides

3. Package

In Roll ID 76mm-105mm

4. Technical Parameter

Single Side Semi-conductive | |||||||||

Thickness | Mass Per Area | Tensile Strength | Elong- ation | Swelling Speed | Swelling Height | Surface Resistance | Volume Resistance | Moisture Content | |

mm | g/m2 | N/cm | % | mm/1,0 | mm/3,0 | Ω | Ω.cm | % | |

0.25±0.03 | 90±5 | ≥25 | ≥12 | ≥6 | ≥8 | ≤1500 | <1x10(6) | ≤9 | |

0.30±0.03 | 100±5 | ≥30 | ≥12 | ≥8 | ≥12 | ≤1500 | <1x10(6) | ≤9 | |

0.35±0.03 | 110±5 | ≥35 | ≥12 | ≥10 | ≥14 | ≤1500 | <1x10(6) | ≤9 | |

0.40±0.03 | 130±10 | ≥40 | ≥12 | ≥11 | ≥15 | ≤1500 | <1x10(6) | ≤9 | |

0.45±0.03 | 140±10 | ≥45 | ≥12 | ≥12 | ≥16 | ≤1500 | <1x10(6) | ≤9 | |

0.50±0.03 | 160±10 | ≥50 | ≥12 | ≥12 | ≥18 | ≤1500 | <1x10(6) | ≤9 | |

Short Term Stability:230 ℃ Long Term Stability: 90 ℃ | |||||||||

Double Sides Semi-conductive | |||||||||

Thickness | Mass Per Area | Tensile Strength | Elong- ation | Swelling Speed | Swelling Height | Surface Resistance | Volume Resistance | Moisture Content | |

mm | g/m2 | N/cm | % | mm/1,0 | mm/3,0 | Ω | Ω.cm | % | |

0.25±0.03 | 100±5 | ≥25 | ≥12 | ≥7 | ≥10 | ≤1500 | <1x10(6) | ≤9 | |

0.30±0.03 | 110±5 | ≥30 | ≥12 | ≥8 | ≥12 | ≤1500 | <1x10(6) | ≤9 | |

0.35±0.03 | 120±5 | ≥35 | ≥12 | ≥9 | ≥13 | ≤1500 | <1x10(6) | ≤9 | |

0.40±0.03 | 130±10 | ≥40 | ≥12 | ≥10 | ≥14 | ≤1500 | <1x10(6) | ≤9 | |

0.50±0.03 | 160±10 | ≥50 | ≥12 | ≥12 | ≥16 | ≤1500 | <1x10(6) | ≤9 | |

Short Term Stability:230 ℃, Long Term Stability: 90℃ | |||||||||

5. Download PDF document

Single Side Non-conductivity | ||||||||

Thickness | Mass Per Area | Tensile Strength | Elong- ation | Swelling Speed | Swelling Height | Short Term Stability | Long Term Stability | Moisture Content |

mm | g/m2 | N/cm | % | mm/1,0 | mm/3,0 | ℃ | ℃ | % |

0.1±0.01 | 40±5 | ≥18 | ≥12 | ≥3 | ≥4 | 230 | 90 | ≤6 |

0.15±0.03 | 60±5 | ≥20 | ≥12 | ≥5 | ≥8 | 230 | 90 | ≤6 |

0.18±0.03 | 65±5 | ≥25 | ≥12 | ≥6 | ≥9 | 230 | 90 | ≤6 |

0.20±0.03 | 70±10 | ≥30 | ≥12 | ≥12 | ≥12 | 230 | 90 | ≤6 |

0.25±0.03 | 80±10 | ≥30 | ≥12 | ≥12 | ≥12 | 230 | 90 | ≤6 |

0.30±0.03 | 90±10 | ≥35 | ≥12 | ≥12 | ≥12 | 230 | 90 | ≤6 |

Double Sides Non-conductivity | ||||||||

Thickness | Mass Per Area | Tensile Strength | Elong- aion | Swelling Speed | Swelling Height | Short Term Stability | Long Term Stability | Moisture Content |

mm | g/m2 | N/cm | % | mm/1,0 | mm/3,0 | ℃ | ℃ | % |

0.18±0.01 | 65±10 | ≥25 | ≥12 | ≥4 | ≥6 | 230 | 90 | ≤6 |

0.20±0.03 | 70±10 | ≥28 | ≥12 | ≥6 | ≥9 | 230 | 90 | ≤6 |

0.25±0.03 | 80±10 | ≥35 | ≥12 | ≥8 | ≥12 | 230 | 90 | ≤6 |

0.30±0.03 | 90±10 | ≥40 | ≥12 | ≥10 | ≥14 | 230 | 90 | ≤6 |

0.35±0.03 | 100±10 | ≥40 | ≥12 | ≥10 | ≥14 | 230 | 90 | ≤6 |

0.20±0.03 | 75±10 | ≥35 | ≥12 | ≥10 | ≥12 | 230 | 90 | ≤6 |

0.25±0.03 | 85±10 | ≥35 | ≥12 | ≥12 | ≥15 | 230 | 90 | ≤6 |

0.50±0.03 | 130±10 | ≥45 | ≥12 | ≥12 | ≥16 | 230 | 90 | ≤6 |